Grease separators for Sewage - KANN Series F

The company LLC "KANN PROJECT" manufactures grease separators of the KANN F series designed to capture fat deposits from wastewater.

The KANN series F grease trap is designed to capture grease deposits from wastewater before connecting to the main sewer. They are used to hold greasy content from discharges at various applications (restaurants, bars, canteens, hotel kitchens, gas stations, etc.). We manufacture ground and underground grease traps in both horizontal and vertical designs, and we always have compact grease traps available for sink installation.

Our wastewater treatment facilities have all the necessary certifications and expert conclusions.

Our wastewater treatment facilities have all the necessary certifications and expert conclusions.

The body of the grease separator KANN is made of low-density polyethylene PE100 with a structured wall of the "KANN" brand in the form of a spiral-wound pipe according to TU BY590844512.003-2018. The material used is corrosion-resistant and completely safe for humans and the environment.

For the treatment of wastewater from industries and car washes containing high levels of mechanical impurities, petroleum products, and various chemicals, KANN series WA wastewater treatment installations (UOOH) can be used.

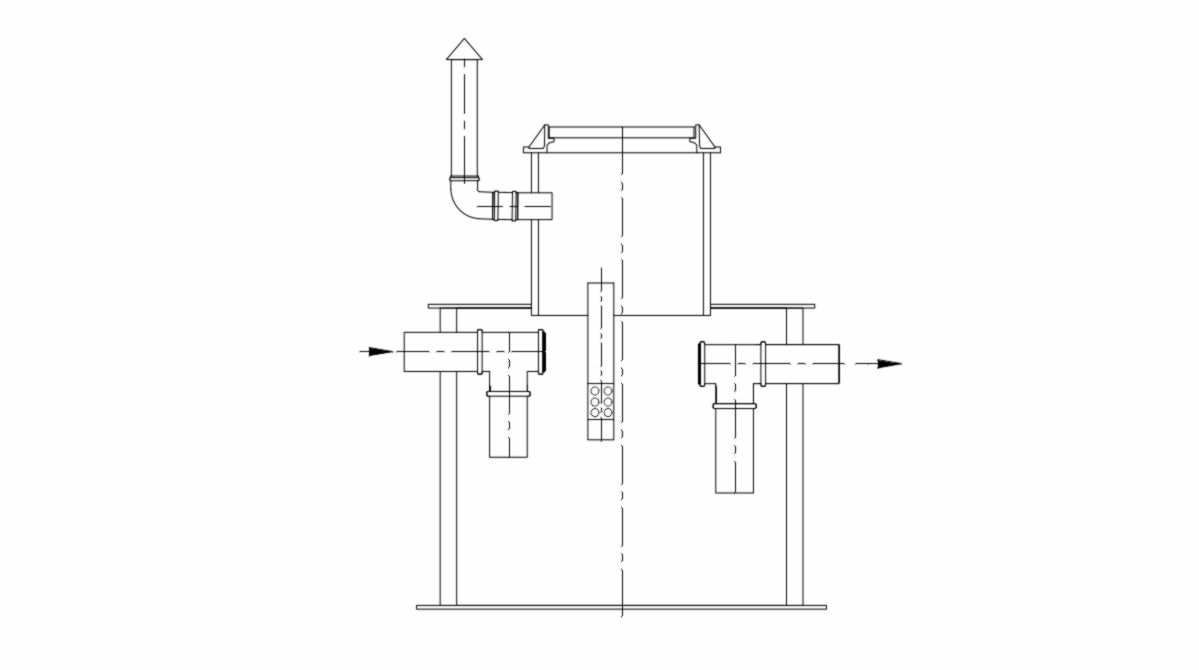

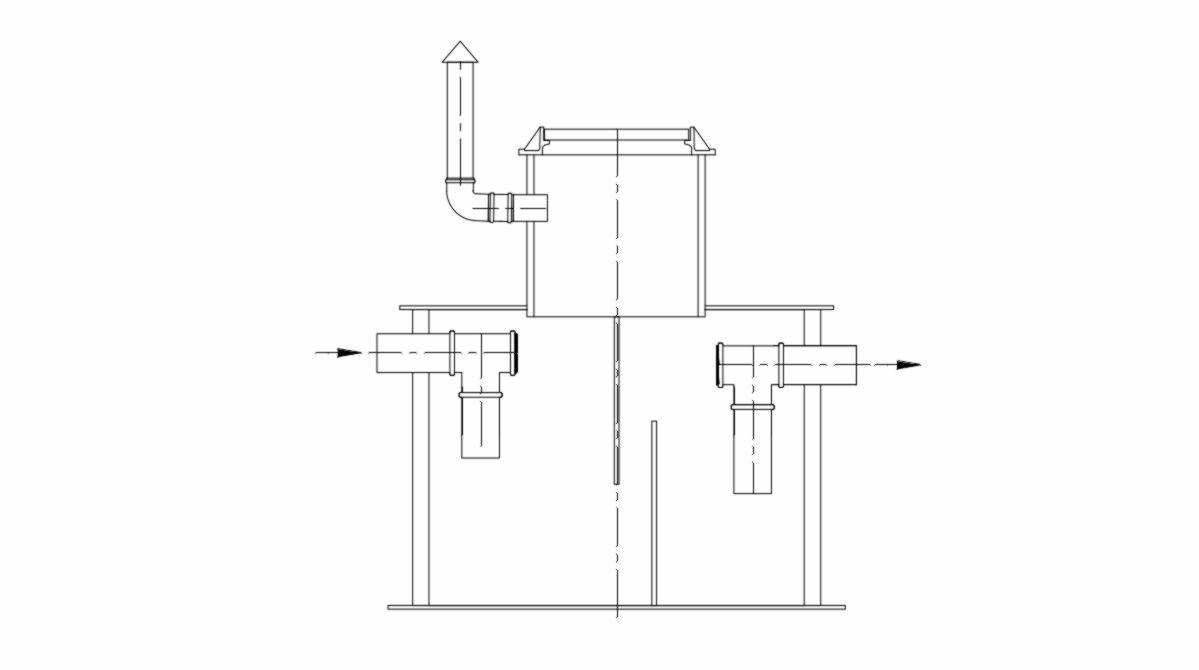

Principle of Operation of the Grease Separator (GS)

The industrial grease trap for sewage is a sealed polyethylene cylindrical container with a technical well and hatch, divided by partitions into several compartments.

Fat trapping occurs due to the difference in density between water and fat particles, resulting in the separation of media (any oils or fats are lighter than water, so they float to the surface).

In the first chamber, suspended particles are separated from the wastewater, settling to the bottom under the influence of gravitational forces. When the effluent enters the second compartment, fat particles rise to the surface of the water, while the treated effluent is discharged into the sewer system or directed to treatment facilities. As accumulation occurs, it is necessary to pump out the sludge and fat layer.

Pumping is carried out through a technical well. The design of the grease trap allows for the accumulation of 150 mm of fat deposits along the water surface in the well in its standard version.

Main characteristics

Fats are insoluble in water; therefore, waste containing fats often leads to clogs in sewage systems. The use of grease traps significantly extends the life of these systems. We offer grease trap models that are compact and can be installed directly under the sink, alongside underground grease traps from the KANN series F, which are capable of processing large volumes of incoming wastewater. We manufacture underground grease traps based on the technical conditions and specific usage requirements of our clients' treatment facilities.

- Performance up to 25 l/s (custom installations with higher performance can be manufactured based on individual specifications);

- Cleaning efficiency for fats up to 80%;

- Diameters in cylindrical shape: 600 mm, 800 mm, 1000 mm, 1200 mm, 1500 mm, 1800 mm, 2050 mm, 2200 mm, 2400 mm, 2800 mm;

- Made from safe polyethylene, resistant to corrosion;

- The service life of the housing is at least 50 years.

Our company LLC 'KANN PROJEKT' offers to purchase grease traps for installation in catering establishments or on the premises of industrial enterprises. We can manufacture a grease trap according to your technical specifications, deliver it to the site, and carry out the installation 'turnkey'. To order a grease trap in Minsk or to get information about our products, please fill out the application on the website or call us.

Local Wastewater Treatment Facilities (LWTF) KANN®

for the treatment of wastewater containing sand, oil, and grease

They represent local wastewater treatment facilities (LWF) designed for the comprehensive treatment of sand-containing and oil-containing surface and industrial wastewater. Oil-containing wastewater can include runoff from garages, parking lots, auto repair shops, gas stations, service stations, fuel depots, parking areas of shopping centers, and compressor station areas.

Local treatment facilities (LTF) designed for the purification of sand-containing surface and industrial wastewater from the infiltration of suspended sand particles and other debris into the stormwater drainage system through sedimentation. Typically, these are discharges on the territory of industrial facilities where there is a high degree of wastewater contamination.

Local treatment facilities (LTF) are designed to purify wastewater containing fats, preventing oily substances from entering the sewage system. These are primarily the wastewater from catering establishments, grocery stores, and manufacturing enterprises in the food industry. These treatment facilities help prevent clogging in urban communications.