Tanks and Reservoirs for Liquids - KANN

Series V, Aboveground and Underground Models

The company LLC "KANN PROJEKT" manufactures reservoirs and containers of the KANN series V for the accumulation, storage, and transfer to end consumers of liquids that are chemically neutral to the material of the reservoir.

Reservoirs of the KANN series V are a universal solution for collecting and storing various liquids (including those containing different impurities).

LLC "KANN PROJECT" specializes in manufacturing high-quality and durable containers made from spiral-wound polyethylene pipe PE100 produced in-house, which can withstand heavy loads and are suitable for working with aggressive media (alkalis, acids, fuels). The sizes of the produced liquid reservoirs range from 1 to 200 m3.

LLC "KANN PROJECT" specializes in manufacturing high-quality and durable containers made from spiral-wound polyethylene pipe PE100 produced in-house, which can withstand heavy loads and are suitable for working with aggressive media (alkalis, acids, fuels). The sizes of the produced liquid reservoirs range from 1 to 200 m3.

The design and characteristics of the container are selected individually for each facility. They can be used in various operating conditions.

Applications: chemical, food industry, medicine, construction, galvanotechnology, etc. Strict control is maintained in production: the quality of welded joints is ensured, and hydraulic tests are conducted. The average service life is 50 years.

Storage tanks are used in manufacturing, light and heavy industries, public services, construction of various facilities, wastewater treatment systems, for storing water and liquids, for collecting and storing domestic and industrial waste, and more.

They can be equipped with various sensors, protective elements, and monitoring systems, allowing for the tracking not only of the product's safety but also its quality during storage.

They can be equipped with various sensors, protective elements, and monitoring systems, allowing for the tracking not only of the product's safety but also its quality during storage.

Thanks to the properties of polyethylene, the color, smell, and taste of drinking water remain unchanged during long-term storage. Drinking tanks are additionally equipped with an air intake filtration system, airtight hatches, and a drainage system for cleaning and disinfecting them.

The material is environmentally safe for humans and the environment. The tanks are resistant to decay and corrosion, do not absorb odors, are easy to clean, and do not develop internal deposits.

The material is environmentally safe for humans and the environment. The tanks are resistant to decay and corrosion, do not absorb odors, are easy to clean, and do not develop internal deposits.

Used for storing liquid for fire extinguishing. They are vertical or horizontal cylindrical tanks. They are installed where there is no water intake from a direct water supply source.

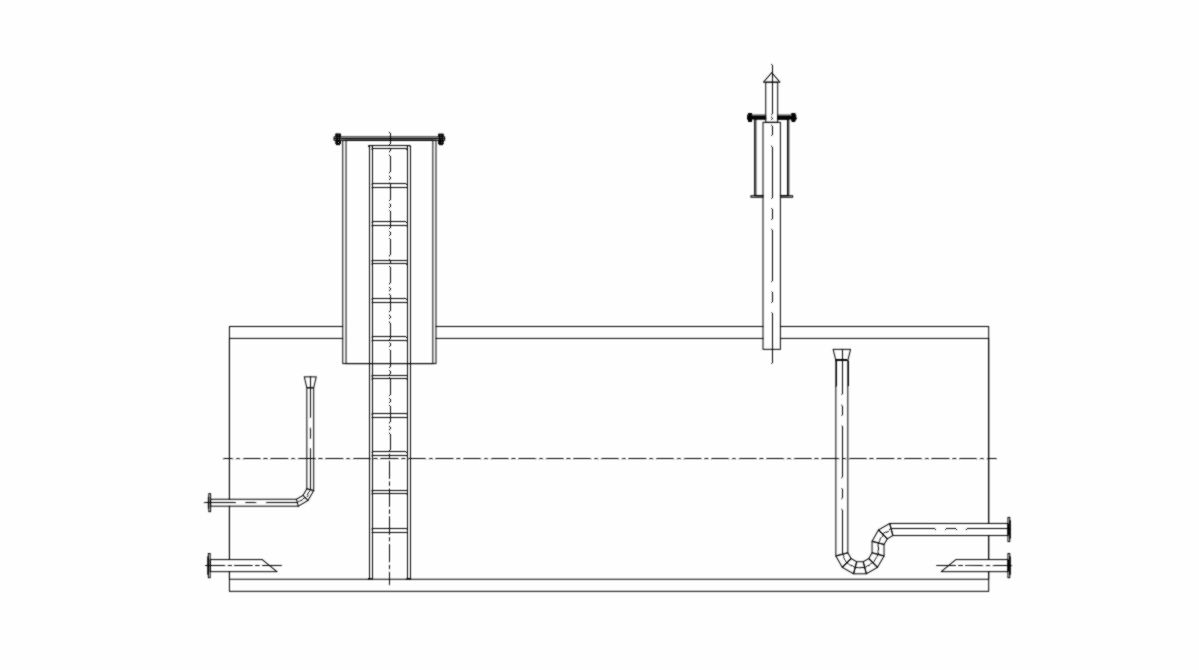

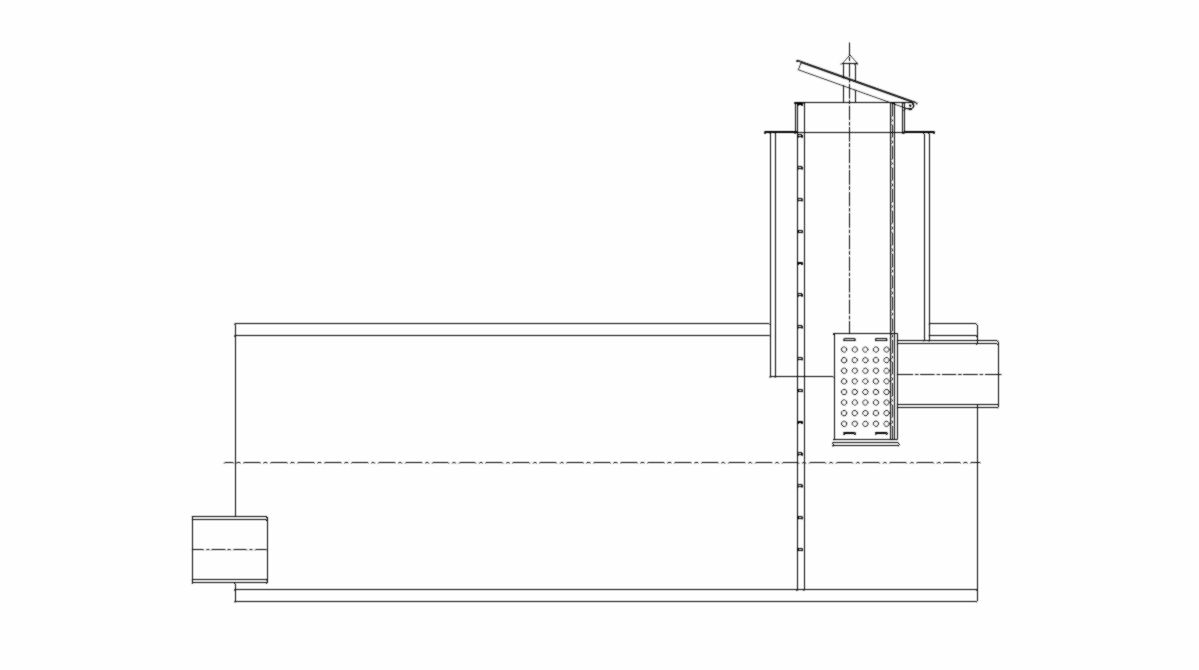

The design includes a drainage pipe for easy liquid drainage; a built-in drainage well; a convenient filling pipe and a suction pipe with a special valve; an overflow pipe.

The design includes a drainage pipe for easy liquid drainage; a built-in drainage well; a convenient filling pipe and a suction pipe with a special valve; an overflow pipe.

They are used for receiving household, storm, and industrial sewage discharges, and for further pumping out by a vacuum truck when fully filled. Typically, they are used in systems for receiving, collecting, and processing rainwater. They are generally applied in situations where it is not possible to connect to a centralized sewage system.

Storage tanks are used for the storage and transportation of various hazardous and particularly hazardous substances, including organic and inorganic acids such as sulfuric, nitric, hydrochloric, and orthophosphoric acids, as well as solid and bulk products, alkalis and salts, alcohols and alcohol-containing liquids, petroleum products including gasoline, diesel fuel, kerosene, and oil, pH-variable and other aggressive media.

Used for the storage and transportation of petroleum products.

Advantages:

- Resistant to chemical agents;

- Repairable;

- Resistant to temperature fluctuations, withstanding a range from -60 to +60 °C;

- Lightweight;

- Environmentally friendly and completely airtight, can be used for over 10 years without repair or dismantling.

Advantages:

- Resistant to chemical agents;

- Repairable;

- Resistant to temperature fluctuations, withstanding a range from -60 to +60 °C;

- Lightweight;

- Environmentally friendly and completely airtight, can be used for over 10 years without repair or dismantling.

Floor Tanks Made of Polyethylene and Polypropylene KANN®

We manufacture plastic containers for liquids in both underground (installation of the container in the ground with subsequent backfilling) and above-ground configurations. The specific type of execution depends on the tasks set and the area of application, and has a number of distinctive properties and advantages. Our company produces above-ground containers from spiral-wound pipe (SWP) and sheet polypropylene, both produced in-house, which undoubtedly represents a significant competitive advantage. The shape, size, and volume of the containers we make are individual and based on your requests.

Advantages of KANN Series V Tanks and Containers

Plastic tanks significantly surpass their metal and concrete counterparts.

Plastic containers from the manufacturer in Minsk have the following advantages:

Plastic containers from the manufacturer in Minsk have the following advantages:

Endurance

In the absence of damage, plastic tanks can last over 50 years.

Strength and Durability

Plastic tanks for sewage effectively handle mechanical loads, as their design features reinforced ribs and partitions.

Corrosion resistance

Unlike metal barrels for sewage, polyethylene products are not susceptible to corrosion. Therefore, they do not become unusable with constant contact with water and damp soil.

Chemical and biological resilience

Plastic storage tanks for sewage are resistant to aggressive environments. They are not affected by chemicals or soil bacteria.

Tightness

The tanks are made from spirally wound pipes produced in-house, which is why we are confident in the tightness of our reservoirs. The contents will not leak into the soil, and groundwater, in turn, will not get inside. Each product undergoes testing under factory conditions.

Quick installation

The lightweight plastic structure does not require a special approach or additional effort for its installation.