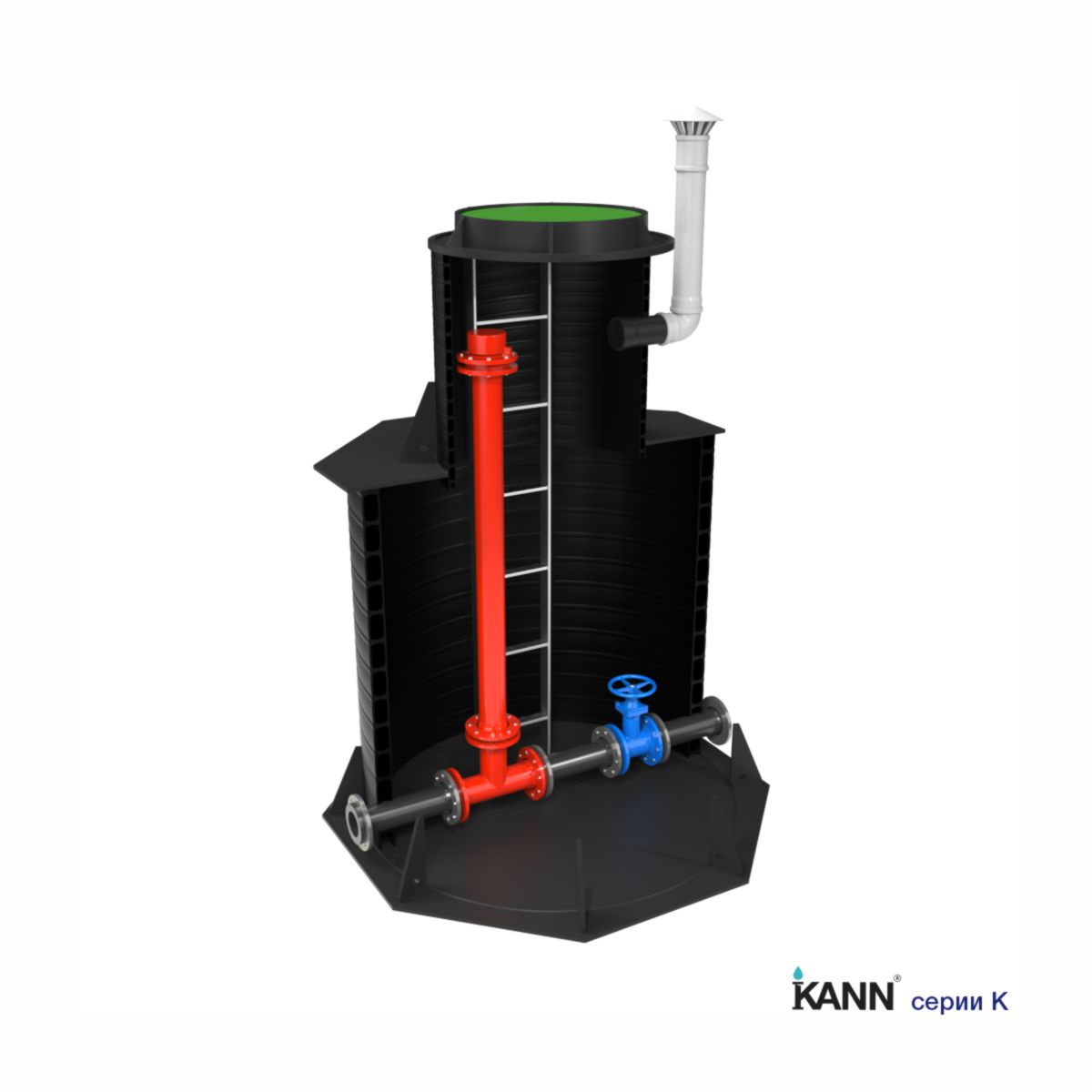

Fire Well KANN Series K

The company LLC "KANN PROJECT" manufactures fire wells KANN K as a modern alternative to reinforced concrete rings in fire protection water supply systems.

Plastic fire wells KANN with fire hydrants are installed on the fire water supply networks. The hydrants are intended for extracting water from the water supply for the needs of fire-fighting equipment; such water supply must be maximally reliable.

Fire protection wells KANN series K are airtight. All connections are thoroughly tested under factory conditions. The wells arrive at the construction site fully factory-prepared, which reduces installation time. The well body is made from KANN spiral-wound polyethylene pipe.

Ring stiffness of the shaft:

From SN2 to SN16 – depending on installation conditions

Diametrical row:

From 400 to 3000 mm

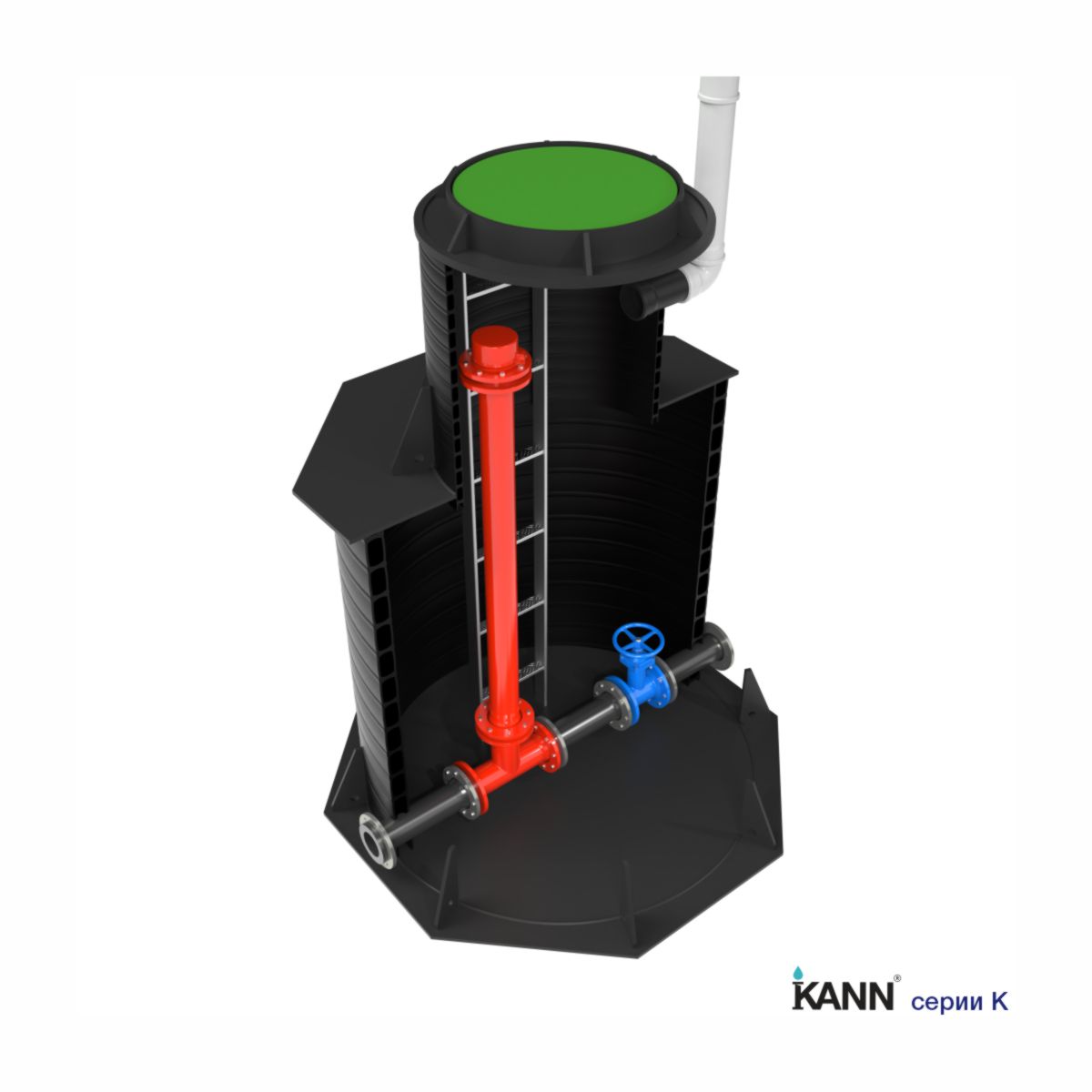

The KANN fire protection wells are delivered to the site in full factory readiness. We produce underground and above-ground wells with hydrants. Typically, wells with fire hydrants are installed along roads at a distance of no more than 2.5 km from the roadway and within 100 meters from the walls of the building.

High quality and thorough quality control ensure a long service life of the products.

All products undergo mandatory certification as well as a testing cycle.

We provide warranty and post-warranty service.

Discounts for wholesale buyers and special conditions for dealers

Fire Wells

KANN Series K

KANN Series K

According to their purpose, we distinguish

2 types:

2 types:

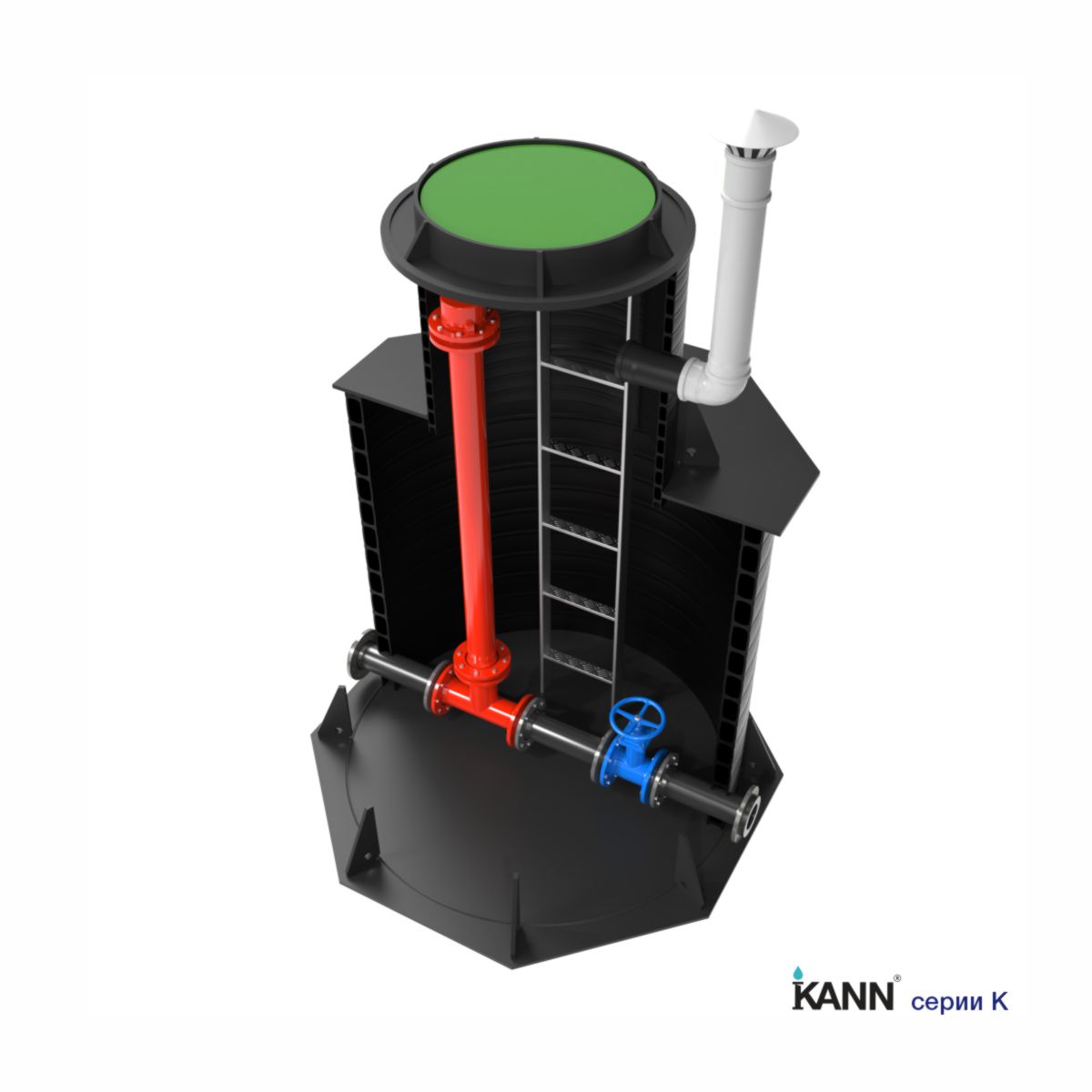

Water pressure boosting well - as a rule, these are dry wells designed for the installation of pressure-boosting pumps, shut-off valves, control instruments, and pressure maintenance systems.

Fire hydrant wells are used for drawing water from the water supply for the needs of fire-fighting equipment on fire water supply networks. Typically, these are underground wells located within 100 meters of the building's walls. The main advantages of using these types of wells include easy and quick access for fire service personnel, as well as the reliability and faultless operation of the fire hydrant itself.

Tray part and chamber for concreting

Functions and Applications

Plastic sewage manholes can have a channel section and a concrete pouring chamber. The space between the bottom of the manhole and its channel section is referred to as the concrete pouring chamber. Two pipes with a diameter of 160 mm in the manhole design are used for pouring concrete. Filling the concrete pouring chamber is only planned on-site during the installation of the sewage manhole. This is done to avoid damage when moving the manhole with a filled chamber.

We offer to purchase a fire fighting well and order installation from our company.

By contacting us, you can purchase a plastic sewer manhole with delivery at the manufacturer's price, and the extensive experience and qualifications of our specialists will allow you to select the fire well design individually, taking into account the customer's technical specifications.

Advantages of KANN® wells

Own manufacture

Manufacture of a well of any complexity. High-quality materials STB ISO 9001

Long service life

The service life of the well is more than 50 years

Easy to install

Ease of installation allows to reduce construction time

Tightness and high durability

The networks are reliably protected from precipitation and temperature changes