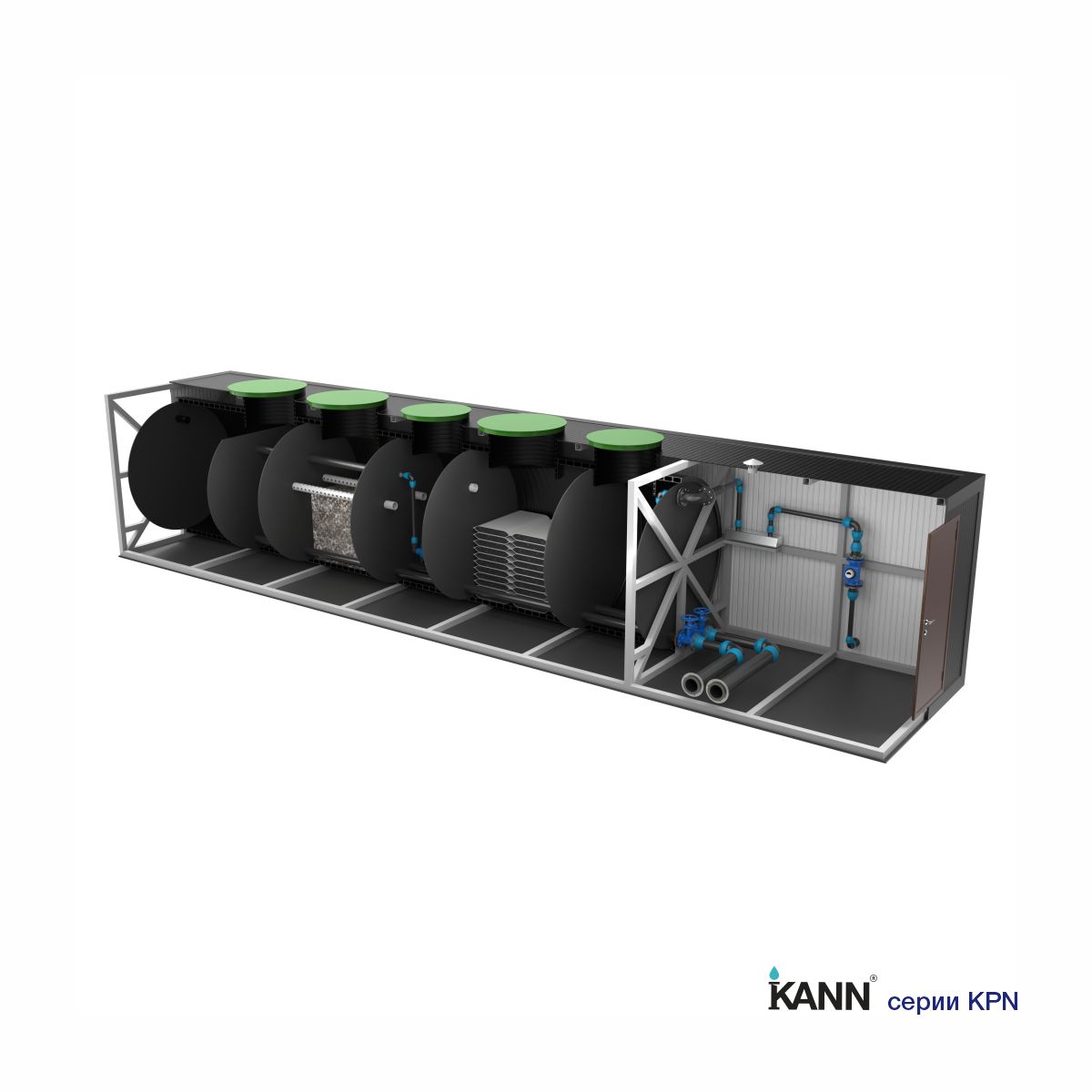

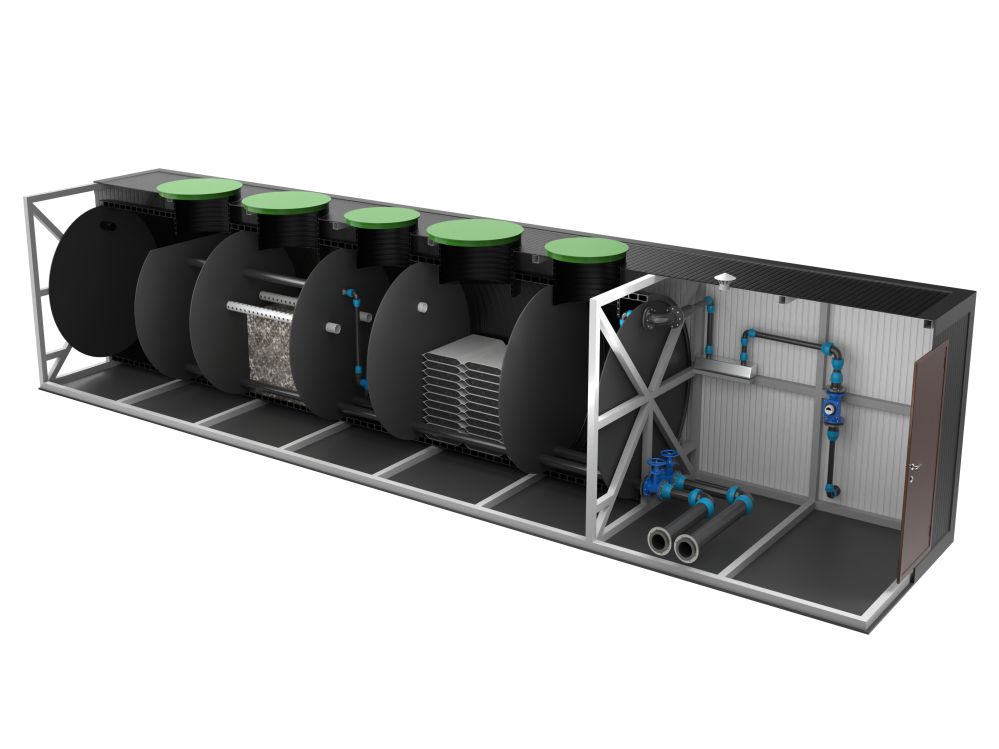

Petroleum Oil Separators (Oil-water separators) KANN KPN Container Type

The company LLC "KANN PROJECT" manufactures container-type sand-oil separators (oil and grease separators) of the KANN KPN series, designed for the treatment of stormwater and industrial wastewater containing sand and oil.

The KANN KPN series oil-water separator (hydrocarbon separator) is a mobile installation with a body made of sandwich panels, designed for the treatment of storm and industrial wastewater by removing suspended particles and hydrocarbons to the regulatory standards permitted for discharge into the centralized storm sewer system or the environment (water bodies, drainage systems, ditches, infiltration systems, evaporation ponds) in accordance with the requirements of the legislation of the Republic of Belarus.

Our wastewater treatment systems have all the necessary certificates and expert conclusions.

Our wastewater treatment systems have all the necessary certificates and expert conclusions.

The wastewater undergoes 3 stages of treatment:

- 1st stage - sedimentation of suspended solids

- 2nd stage - separation of petroleum products and oils

- 3rd stage - post-treatment using sorbents (optional).

The basic configuration of the product includes: a maintenance well kit with shutoff hatches, a coalescent module block, a ventilation riser, and a stationary ladder.

Optionally, the product can be equipped with: remote monitoring system (GSM and/or Ethernet), sand level sensor, oil level sensor, a set of absorbent materials for load, installation straps.

For the treatment of industrial and car wash wastewater containing a large amount of mechanical impurities, petroleum products, and various chemical substances, KANN series WA water treatment plants (WTP) can be used.

Operating Principle of the Sand Oil Separator (SOS):

The wastewater flows by gravity into the first compartment of the treatment facilities - the sand trap. At this stage, the flow is mitigated, and large fractions of debris and sand settle under the influence of gravity.

Then water enters the second compartment - the oil-water separator. Here, with the help of a coalescing module, dissolved petroleum products are separated from the water, and finer suspended particles are settled out. Subsequently, these contaminants are cleaned using a vacuum truck during the maintenance of the treatment facilities.

The water then flows by gravity into the third section, the sorption filter. This part ensures the required results in the treatment of stormwater runoff. As the water passes through the sorbents, it is purified from suspended substances up to 98%, from petroleum products up to 99%, and from biochemical oxygen demand (BOD) up to 96%.

Constructive elements of sand-oil separator:

Sand separators

Designed to trap sand and petroleum products present in surface runoff through gravitational sedimentation. The sand trap's construction effectively retains non-dissolved substances in the runoff. To monitor sediment levels in the sand trap, a sludge level sensor may be included in the supply package of the treatment facilities, if necessary.

Oil separators

It is a structure containing a coalescing module. Polypropylene is a water-repellent material that, when water flows through an oil separator, attracts small particles of hydrocarbon substances to its surface while simultaneously repelling water. As a result, the oil particles coalesce into larger droplets or aggregates, which then rise to the water's surface and form oil slicks that are subsequently pumped out. To monitor the presence of oil products, an oil level sensor may be included in the delivery package of the treatment facilities.

Adsorption filter

Designed for further purification of stormwater from various impurities that were not captured by the oil separator. It consists of several filtering layers: shungite and activated carbon. Shungite has the ability to effectively purify from various pollutants, including organic ones. Water is filtered through the layer of shungite, which distributes the water flow, and then moves to the carbon filter. Activated carbon is one of the best adsorbents for the removal of petroleum products and organic pollutants.

Local Wastewater Treatment Facilities (LWTF) KANN®

for the treatment of wastewater containing sand, oil, and grease

Sand & oil separators KANN®

They represent local wastewater treatment facilities (LWF) designed for the comprehensive treatment of sand-containing and oil-containing surface and industrial wastewater. Oil-containing wastewater can include runoff from garages, parking lots, auto repair shops, gas stations, service stations, fuel depots, parking areas of shopping centers, and compressor station areas.

Such a treatment facility can be used either individually or in conjunction with other treatment systems.

Such a treatment facility can be used either individually or in conjunction with other treatment systems.

Sand separators

KANN®

KANN®

Local treatment facilities (LTF) designed for the purification of sand-containing surface and industrial wastewater from the infiltration of suspended sand particles and other debris into the stormwater drainage system through sedimentation. Typically, these are discharges on the territory of industrial facilities where there is a high degree of wastewater contamination.

Local treatment facilities (LTF) are designed to purify wastewater containing fats, preventing oily substances from entering the sewage system. These are primarily the wastewater from catering establishments, grocery stores, and manufacturing enterprises in the food industry. These treatment facilities help prevent clogging in urban communications.

Доставка песконефтеуловителя KANN KPN

контейнерного типа на объект

контейнерного типа на объект