Catalog of KANN® Polyethylene Wells

Our company manufactures polyethylene (PE) wells based on spiral-wound pipes produced in-house.

Polyethylene wells are an integral part of local wastewater treatment systems. These devices allow for the management of stages and monitoring of treatment processes, as well as providing access to pipelines and equipment.

Advantages of installing plastic wells

in local wastewater treatment systems

Strength and

durability

durability

Polyethylene wells have high strength and durability, ensuring a long service life. They are resistant to corrosion, allowing them to maintain their properties even when used in aggressive environments.

Ease of installation

and transportation

and transportation

Polyethylene wells are lightweight and compact, making their transportation and installation easier. As a result, the costs for delivery and installation of the devices are reduced.

Eco-friendliness

and recycling

and recycling

Polyethylene wells are environmentally friendly and do not have a harmful impact on the environment. This is because they do not release harmful substances and do not pollute the soil and water.

Resistance

to impact

to impact

Polyethylene wells are resistant to sunlight and do not fade over time. This ensures that their appearance is preserved and protects against additional repair and maintenance costs.

Manufacturing according to drawings and requests

There is a possibility of custom manufacturing according to individual dimensions and requirements. This allows them to be used in various conditions and in different areas where a specific size, shape, or functional characteristics are needed.

We offer to order a plastic well and installation from our company

You can order polyethylene manholes for sewage and water supply systems from our company. The material is durable and stable in high humidity conditions. By contacting us, you can purchase a plastic manhole with delivery at manufacturer prices, and our extensive experience and qualifications allow us to select the design of the polyethylene manhole individually, taking into account the customer's technical specifications.

Operating principle

Functions and Applications

Polyethylene wells are used in local wastewater treatment systems to manage cleaning processes and ensure access to equipment. They are enclosed polyethylene containers that are installed in the ground and connected to the piping system. Pumps, valves, and other equipment for managing the treatment processes are installed in the wells.

The use of polyethylene wells in local wastewater treatment systems offers numerous advantages, including high strength, durability, corrosion resistance, airtightness, and the ability to manufacture according to individual sizes and requirements. This makes them one of the most popular solutions for collecting and processing liquids in infrastructure and industry.

Advantages of KANN® plastic wells

Plastic wells are widely used in the housing and communal services sector for the installation of sewage and water supply systems. Unlike traditional concrete structures, plastic wells:

- Ensure complete tightness throughout their service life;

- Can withstand high mechanical loads;

- Provide strength and tightness at the points of pipe and cable entry;

- Are easy to install;

- Have a low weight;

- Are resistant to temperature fluctuations;

- Do not require replacement for up to 50 years.

The depth of burial and the choice of device type depend on the groundwater level on the site, soil characteristics, and possible loads. For accurate calculation, we recommend consulting our specialists.

Plastic wells for water supply can be connected to any type of pipe: pressure polyethylene, polyvinyl chloride, corrugated non-pressure, and steel pipes.

- Ensure complete tightness throughout their service life;

- Can withstand high mechanical loads;

- Provide strength and tightness at the points of pipe and cable entry;

- Are easy to install;

- Have a low weight;

- Are resistant to temperature fluctuations;

- Do not require replacement for up to 50 years.

The depth of burial and the choice of device type depend on the groundwater level on the site, soil characteristics, and possible loads. For accurate calculation, we recommend consulting our specialists.

Plastic wells for water supply can be connected to any type of pipe: pressure polyethylene, polyvinyl chloride, corrugated non-pressure, and steel pipes.

Polyethylene wells can also be manufactured with additional openings and channels, providing greater flexibility in installation and use. For example, they can be used for collecting and draining rainwater or for the collection and recycling of industrial waste. Due to the ability to manufacture according to individual requirements, polyethylene wells can be utilized in various industries and infrastructure where unique solutions for the collection, recycling, and disposal of liquids are required.

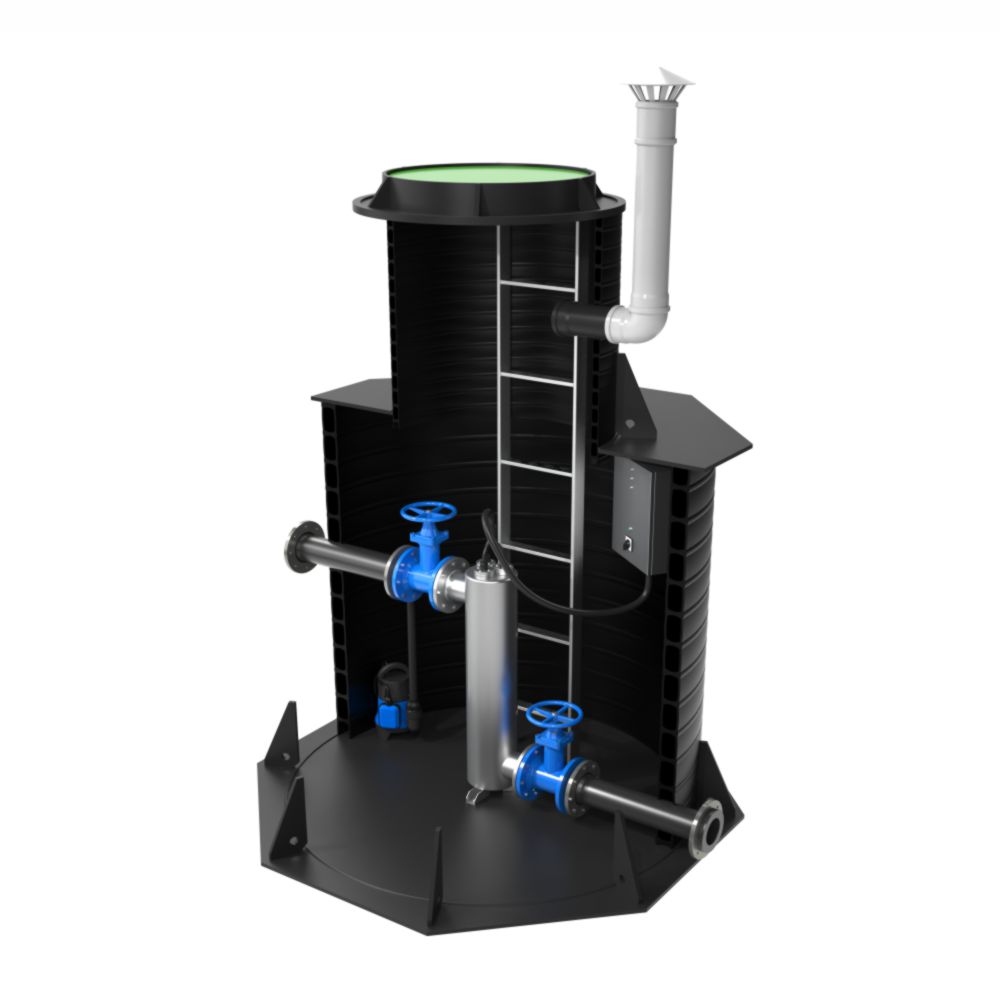

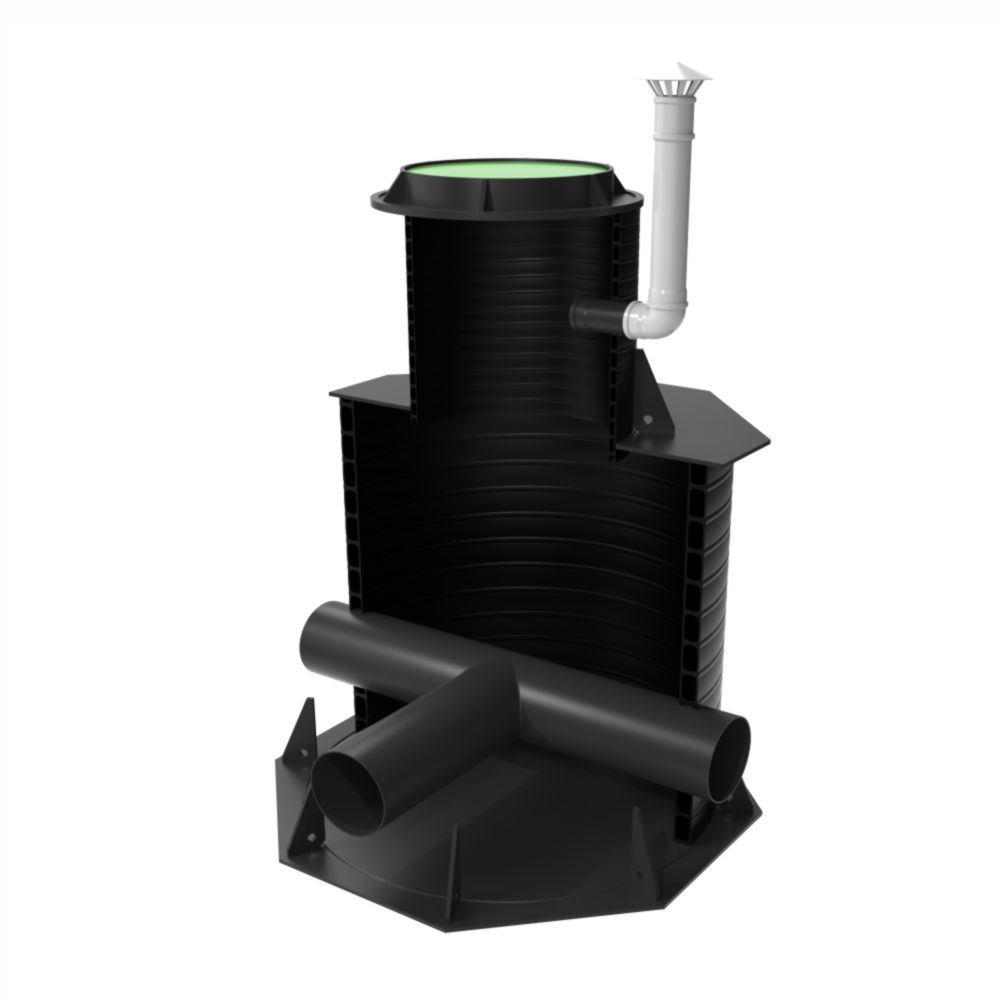

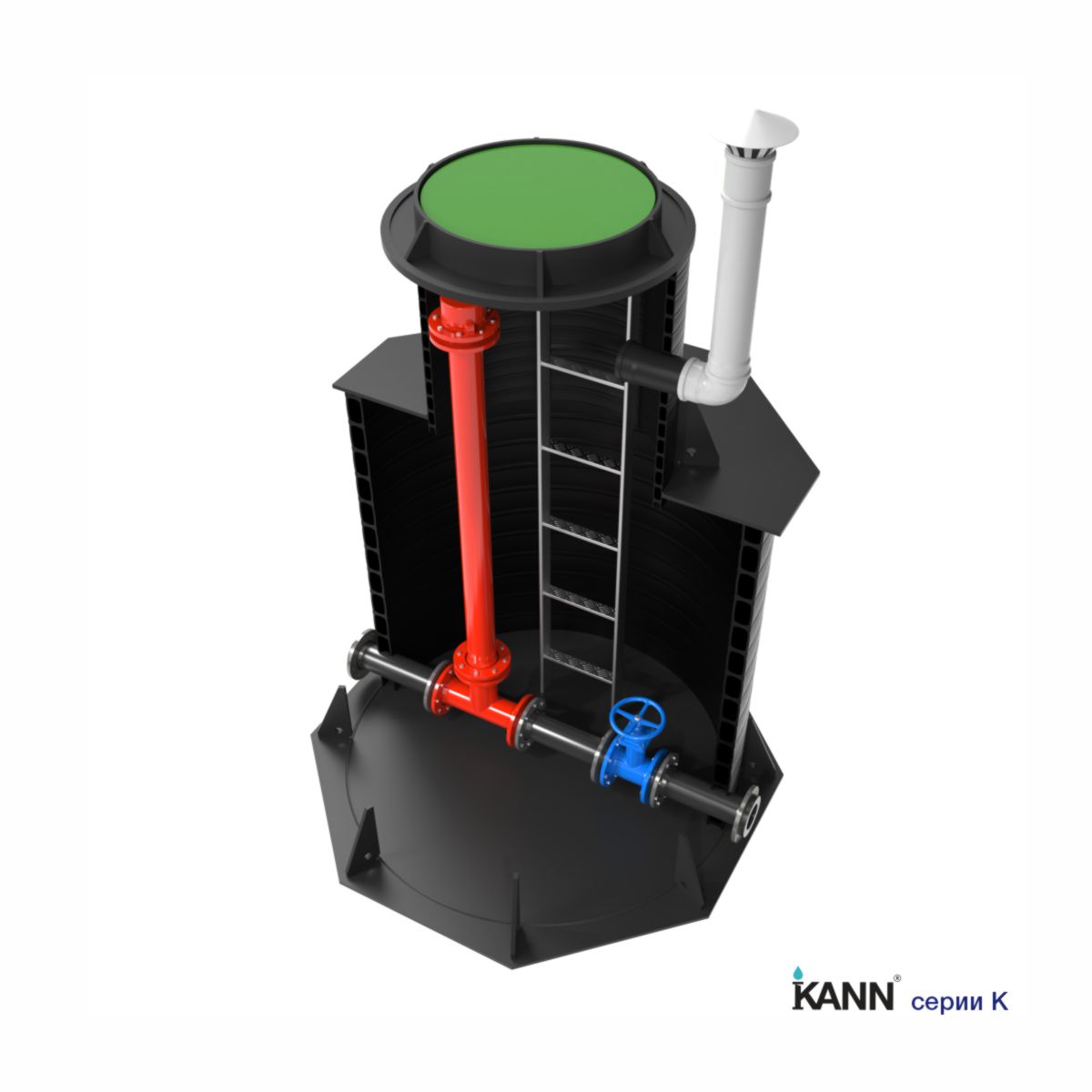

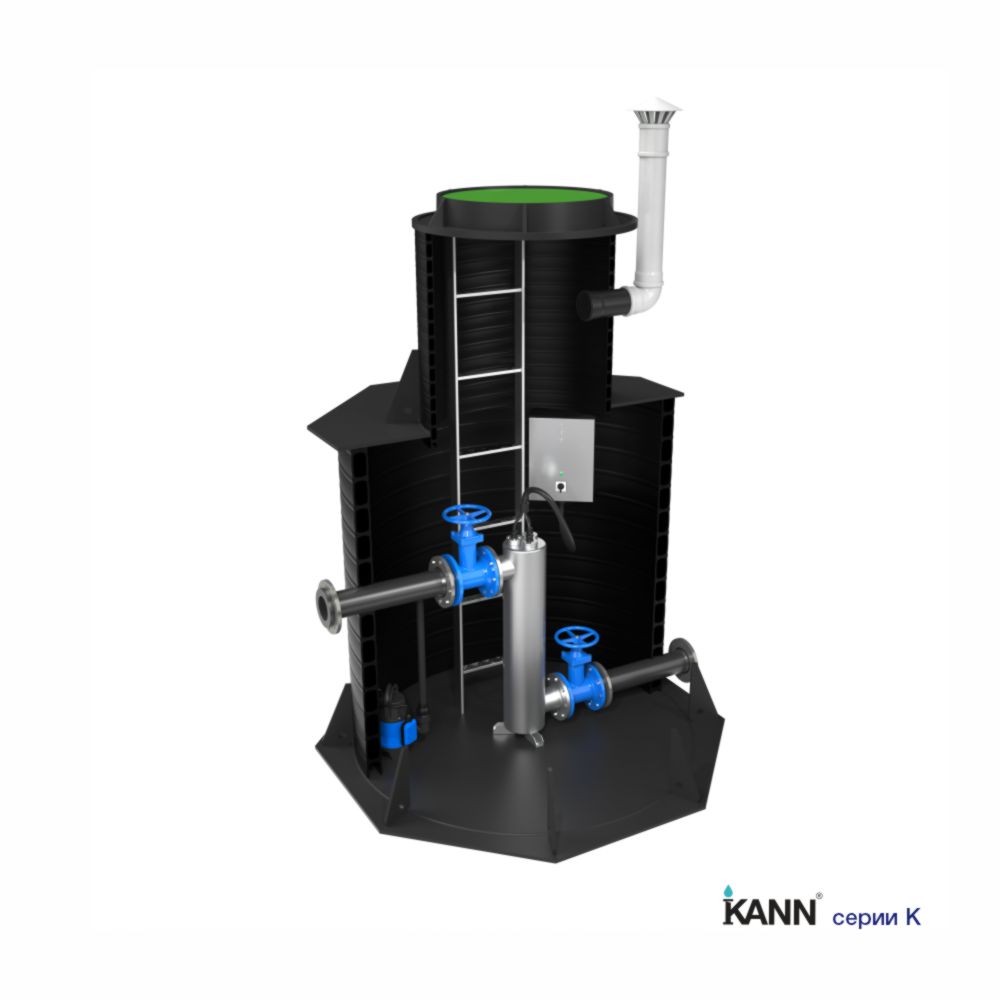

Polyethylene wells KANN®

K series

K series

Main design elements:

Bottom - almost all types of wells have a solid bottom, but it can also be perforated.

The body is a spiral-wound pipe (SWP) of cylindrical shape with fittings and other additional elements welded into it.

Additional reinforcing elements - the larger the volume of the structure, the lower its stiffness. Therefore, during the assembly of wells, additional parts are used to increase the body's resistance to mechanical loads.

The neck is an element that is present in almost all plastic wells, and its height depends on the depth of the wastewater treatment system installation.

The hatch prevents the entry of debris and foreign liquids into the well while providing easy access.

| Our website offers polyethylene water supply wells at competitive prices directly from the manufacturer. In our catalog, you will find everything you need for the installation of drainage and sewage systems: spiral-wound pipes, pumping stations, sand traps, recycled water treatment systems, caissons, reservoirs, biological treatment stations, and more. |