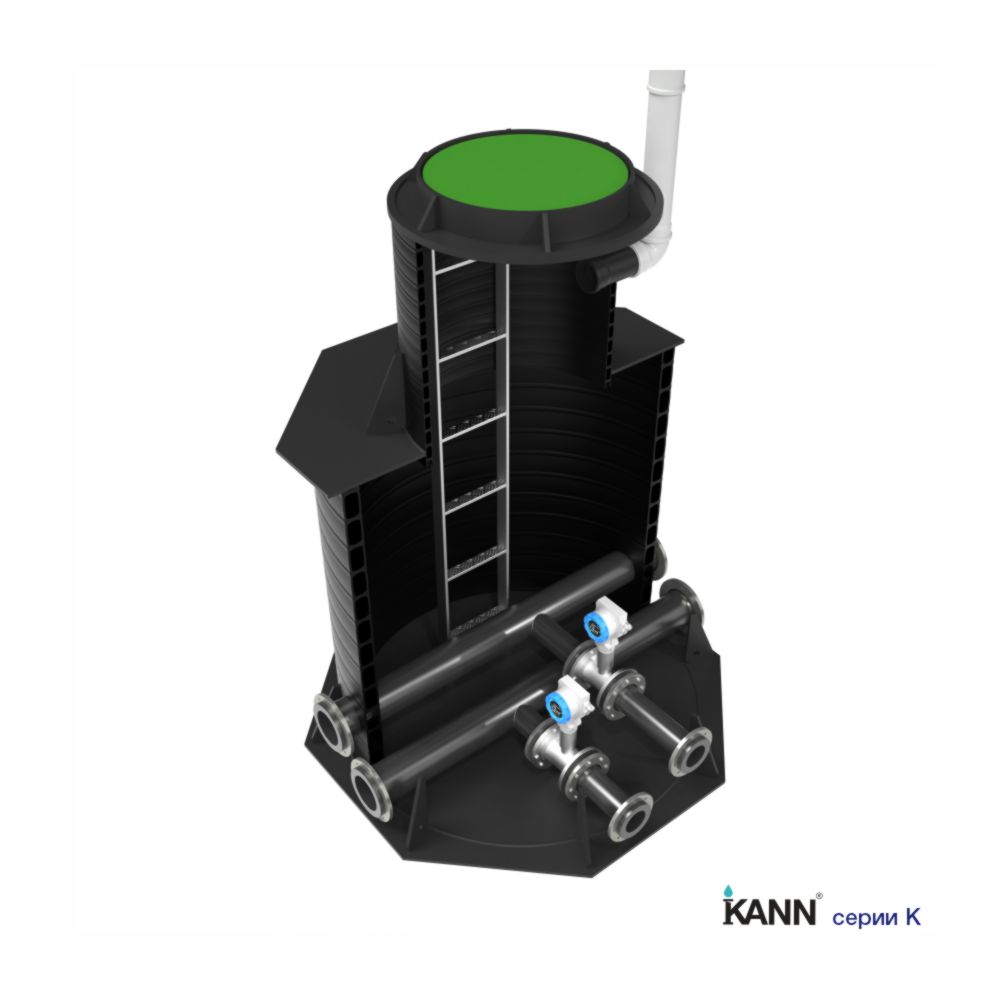

Well of the flow meter unit KANN series K

The company LLC 'KANN PROJECT' produces KANN K metering well units designed primarily for measuring the volume of water flowing through the system.

The primary function of the KANN series K flowmeter well is to measure the flow of water passing through the purification system at the outlet, as well as to monitor the quality of the purified water along with the mechanical protection of the flowmeter unit components.

The KANN series K metering well chambers are completely sealed. All connections undergo inspection in factory conditions. The chambers arrive at the construction site fully factory-ready, which reduces installation time. The chamber body is made from a spirally wound polyethylene pipe SVT KANN and features a monolithic welded construction.

Кольцевая жесткость шахты:

От SN2 до SN16 – в зависимости от условий установки

Диаметральный ряд:

От 400 до 3000 мм

The wells of the metering unit are an important component of the local wastewater treatment system. They provide accurate measurement of flow and control the quality of treated water at the outlet. The combined use of polyethylene wells and HDPE pipes ensures the tightness of sewer systems and trouble-free operation for many years.

High quality and thorough quality control ensure a long service life of the products.

All products undergo mandatory certification as well as a testing cycle.

We provide warranty and post-warranty service.

Discounts for wholesale buyers and special conditions for dealers

Well of the flow meter unit

KANN series K

KANN series K

Основные преимущества:

Wastewater consumption monitoring enables the control of the volume of wastewater entering treatment facilities, as well as the precise determination of the amount of treated water that can be discharged into the natural environment.

Quality control of wastewater - the metering unit allows monitoring the water quality passing through the treatment system. For this purpose, the unit is equipped with special sensors that can measure water parameters such as pH, temperature, level of pollution, etc.

Monitoring of the treatment process - the flow measurement unit allows monitoring of the wastewater treatment process. Data obtained from sensors help determine the efficiency of the treatment system and identify potential issues in its operation. It can be equipped with a remote monitoring system, allowing for remote control of the treatment process.

The wells of the metering unit are an important component of the local wastewater treatment system. They ensure accurate measurement of flow rates and monitor the quality of the treated water exiting the treatment system. The correct selection and installation of the well, as well as the use of high-quality sensors, are essential for the long and uninterrupted operation of the entire local treatment system.

Advantages of

the device

the device

Functions and Applications

The well of the metering unit is a vertical cylinder that is installed on a pipeline through which wastewater flows. Inside the well, there are sensors that measure the flow and quality of the water exiting the treatment system. The well typically features access openings for servicing the sensors and allows for their replacement when necessary.

Particular attention must be paid to the selection of sensors to be used in the well of the metering unit. The sensors should be high-quality, accurate, and reliable. They must comply with the requirements of regulatory documentation and be installed according to the manufacturer's recommendations.

We offer to purchase a metering well unit and order installation from our company.

By contacting us, you can purchase a plastic flow measurement well with delivery at the manufacturer's price. Our extensive experience in solutions and the qualifications of our specialists will allow you to select the well design individually, taking into account the conditions of the customer's technical assignment.

Advantages of KANN® wells

Own manufacture

Manufacture of a well of any complexity. High-quality materials STB ISO 9001

Long service life

The service life of the well is more than 50 years

Easy to install

Ease of installation allows to reduce construction time

Tightness and high durability

The networks are reliably protected from precipitation and temperature changes