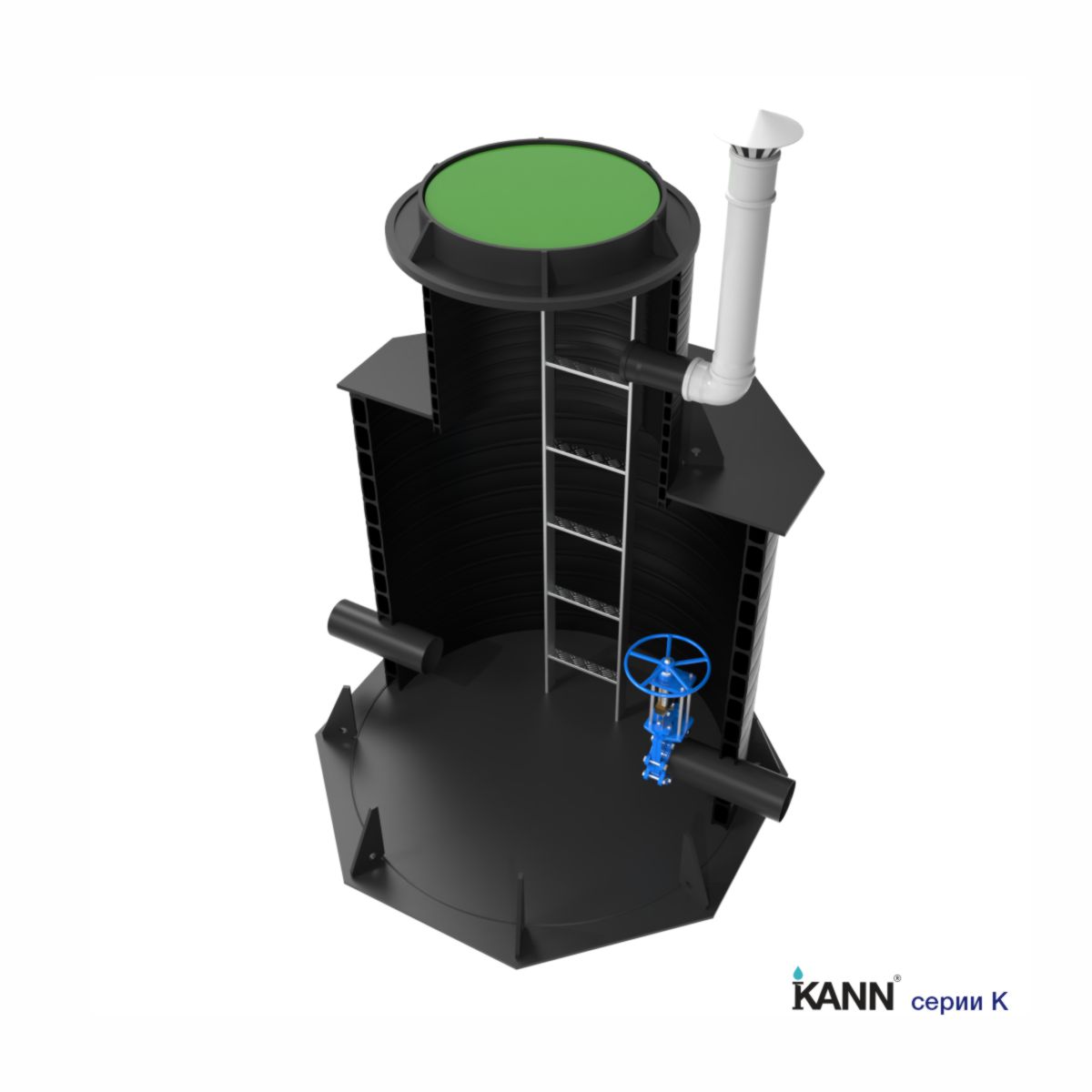

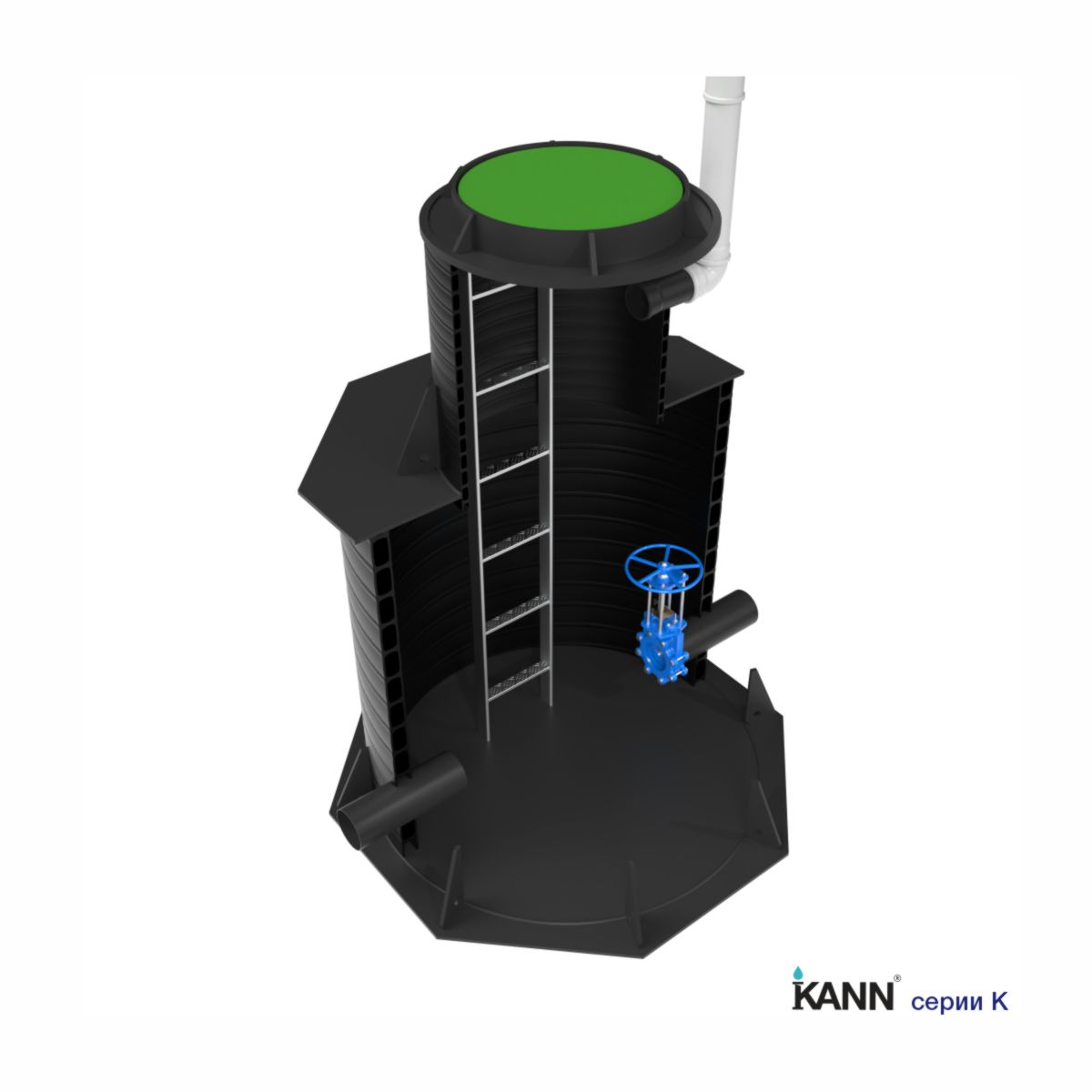

Sampling Well KANN Series K

The company LLC "KANN PROJECT" manufactures KANN K sample extraction wells designed for collecting treated water from local wastewater treatment facilities (LWTF).

The KANN K sampling well, in other words, the monitoring well, serves as the final component in the local treatment facility (LTF) system.

The main purpose of the inspection well is to provide access to the collection of treated effluents for quality control inspection. The wells are airtight and undergo quality control in factory conditions. The wells are delivered to the construction site fully factory-ready, which reduces installation time. The well body is made of spiral-wound polyethylene pipe SVT KANN and features a monolithic welded structure.

Кольцевая жесткость шахты:

От SN2 до SN16 – в зависимости от условий установки

Диаметральный ряд:

От 400 до 3000 мм

We manufacture inspection manholes equipped with a damper. These components of the sewage system have varying flow capacities. The joint use of polyethylene manholes and HDPE pipes ensures the tightness of sewage systems and trouble-free operation for many years.

High quality and thorough quality control ensure a long service life of the products.

All products undergo mandatory certification as well as a testing cycle.

We provide warranty and post-warranty service.

Discounts for wholesale buyers and special conditions for dealers

Sampling Well

KANN Series K

KANN Series K

Allow to implement:

Quality Control

Production control

Monitor the composition and properties of wastewater (industrial, domestic)

Evaluate the results of repair work on the production site.

The work on the maintenance of the treatment facilities can include control wells equipped with disk valves, which can be closed for servicing the treatment plants in the event of exceeding the maximum allowable concentrations for any of the indicators.

For this category of equipment, the material from which the housing is made is important. The control manholes for wastewater sampling are made from composite materials, which provides the products with many advantages. The benefits of these products, compared to concrete installations, include: high resistance to aggressive environments, absolute tightness, minimal thermal conductivity, lightweight, and low operating costs.

Functional Features of the Well

Placement and arrangement

The sampling well is installed after the treatment facilities but before the discharge point of the treated effluent into the sewage system, ditch, or lawn. At the bottom of the control well, there is a sedimentation chamber. It is necessary for mixing the treated water flow and taking samples for laboratory assessment.

The control-type device consists of a manhole cover, a neck, a working chamber, a shaft, and a bottom part.

We offer to purchase a sampling well and order installation from our company.

By contacting us, you can purchase a plastic sewage manhole with delivery at the manufacturer's price. Our extensive experience and the qualifications of our specialists will allow us to select the design of the sampling manhole individually, taking into account the conditions of the customer's technical assignment.

Advantages of KANN® wells

Own manufacture

Manufacture of a well of any complexity. High-quality materials STB ISO 9001

Long service life

The service life of the well is more than 50 years

Easy to install

Ease of installation allows to reduce construction time

Tightness and high durability

The networks are reliably protected from precipitation and temperature changes